We all agree with what the PwC report suggests, “Internet of Things is transforming the everyday physical objects that surround us into an ecosystem of information that will enrich our lives. From refrigerators to parking spaces to houses, the Internet of Things is bringing more and more things into the digital fold every day, which will likely make the Internet of Things a multi-million dollar industry in the near future.”

Our most recent blog taught us how IoT solutions turn traditional businesses into more brilliant businesses through digitalization. One of its crucial roles has been in large-scale industries and enterprises. In today’s blog, we’ll delve into some of the significant trends and benefits of the industrial Internet of Things (IIoT) and learn about its global position. But first, let’s understand the industrial IoT industry in detail.

Industrial Internet of Things (IIoT): Meaning

Regarding IIoT, we mean using IoT services in industrial applications. Its primary purpose is to enhance existing industrial systems through increased productivity and efficiency. During the early 19th century, industries saw the mechanization of production with the development of machines. In the second and third industrial revolutions, electricity, mass production, and automation came to light.

Today, we are finally at the fourth industrial revolution, Industry 4.0. Led by the Internet of Things solutions, this revolution is driven by revolutionary developments such as the rise of data and connectivity, analytics, artificial intelligence, human-machine interaction, and advancements in robotics. This brought the benefits of automation and intelligent or IoT manufacturing.

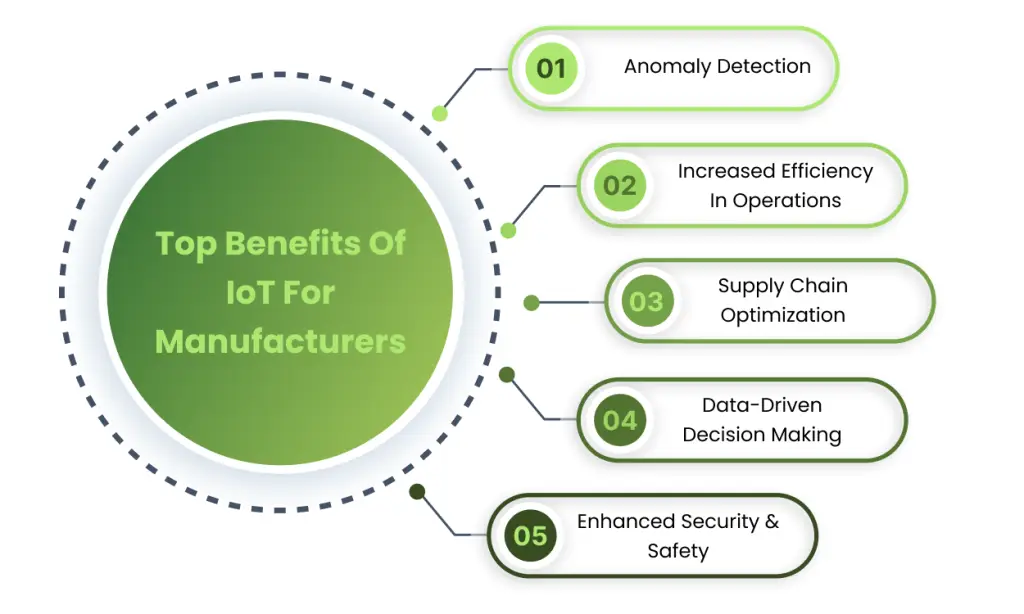

Top Benefits of IIoT For Manufacturers

When we talk about the role of IoT in manufacturing, it improves efficiency, productivity, and job quality while lowering overall production costs. IoT enables digital transformation by connecting a vast network of sensors, machines, and robots.

IIoT also enables the creation of smart factories where machines interact and collaborate smoothly, resulting in enhanced efficiency, decreased downtime, and higher product quality. Let’s discuss some of its real-time benefits in detail:

Anomaly Detection

IIoT systems continuously monitor equipment and processes for deviations from standard operating parameters. This enables the early discovery of anomalies such as equipment failures, unexpected production slowdowns, and quality difficulties. By proactively addressing these challenges, producers may reduce downtime and waste and improve overall product quality.

Increased Efficiency in Operations

IoT in manufacturing gives real-time data on machine performance, production processes, and resource utilization. With this thorough information, manufacturers can adjust their operational processes, streamline workflows, and identify areas for improvement that will lead to increased production.

The data-driven strategy enables firms to optimize production schedules, detect bottlenecks, and increase resource usage. IIoT enables manufacturers to enhance production and save costs by streamlining operations and reducing inefficiencies.

Supply Chain Optimization

The use of an IoT system will also allow for the availability of real-time supply chain information. Products and supplies will be easier to track, revealing bottlenecks and inefficiencies. Plants will be linked to suppliers via the cloud. All parties can track the necessary information to anticipate problems and immediately handle inventory reductions.

By integrating devices and systems throughout the supply chain, manufacturers can track raw material movement, check inventory levels, and improve logistics. This leads to better inventory management, quicker order fulfillment, and shorter lead times.

Data-Driven Decision Making

IoT in manufacturing enables real-time data monitoring and analysis, allowing for early defect discovery and product quality assurance. It also ensures that producers meet all of the quality checklist requirements. This demonstrates higher consumer happiness, increased brand loyalty, and fewer product and warranty claim concerns and issues.

Manufacturers can use data analytics to make more informed decisions about production planning, resource allocation, and process improvements. This data-driven strategy allows manufacturers to improve their operations and achieve a competitive advantage.

Enhanced Security and Safety

The Internet of Things is well-suited to big data analysis. Key health and safety performance indicators can thus be continuously examined to provide better workplace conditions. Lagging signs, such as the frequency of accidents, can be rectified promptly.

IoT sensor makers developed gadgets that provide accurate insights and information on industrial access. It covers machine and asset condition monitoring and predictive maintenance assessment. Manufacturers can create a safer and more reliable work environment for their employees by putting security and safety first.

Latest IIoT Trends

Industrial IoT has brought a revolution through data sensors, automation, higher operational efficiency, and improved supply chains in the recent technological age. As a result, implementing IoT in manufacturing will save costs, enhance production quality, and increase process speed. Here are some of the latest IIoT trends we’ll observe in 2025:

Higher exchange of data

Integration of AI and ML

Wireless Solutions

Edge Computing

Digital Twin Technology

Sustainable Manufacturing

Quality Assurance & Monitoring

Predictive Maintenance

Conclusion

In today’s competitive industrial market, digitalization is the key to success. With the revolutionary impact of IoT trends in manufacturing, no doubt those who opt for traditional solutions are likely to fall behind. This can significantly impair a manufacturer’s capacity to remain competitive, efficient, and profitable in today’s fast-changing industrial market.

At last, including IoT manufacturing solutions can help you gain higher productivity and efficiency in 2025. Hiring a tech-driven software development company is crucial to drive innovation and achieve optimal support. Hire Echoinnovate IT today and share details of your business needs with us.

FAQs: The Industrial IoT Revolution: Benefits for Manufacturers

What is Industrial IoT (IIoT) and how does it benefit manufacturers in 2025?

Industrial IoT (IIoT) refers to the use of connected devices and sensors in manufacturing environments to collect and analyze data. In 2025, IIoT helps manufacturers improve efficiency, reduce downtime, and optimize production by providing real-time data insights for better decision-making.

How does IIoT improve efficiency in manufacturing operations?

IIoT enhances efficiency by enabling predictive maintenance, automating routine tasks, and monitoring equipment performance in real time. This reduces unexpected failures, lowers maintenance costs, and streamlines production workflows, leading to higher productivity.

What role does data analytics play in the Industrial IoT revolution for manufacturers?

Data analytics in IIoT allows manufacturers to analyze large amounts of real-time data collected from connected devices. This helps identify trends, optimize operations, and make informed decisions that improve overall efficiency, quality control, and supply chain management.