In today’s technology world, the digital revolution has caused significant changes in various industries, including product engineering. Businesses must embrace digital transformation strategies to be competitive and fulfil changing client demands. This article examines the future of product engineering, focusing on emerging technologies like IoT, AI, cloud computing, and automation tools that drive innovation. Furthermore, sustainable engineering solutions, data-driven product development, and predictive analytics will be explored as essential components of the future of product engineering.

Firms must build solid digital transformation strategies to adopt the future of product engineering successfully. These solutions require incorporating digital technologies into every stage of the product development process, from concept to manufacturing. They enable businesses to streamline processes, increase efficiency, and improve customer service. Companies can create new development and innovation opportunities by leveraging developing engineering technologies.

Key Advantages of Product Engineering

There are various benefits to employing product engineering tactics in your firm. One of the primary benefits of product engineering is increased personalization. Businesses that use a product engineering approach can adjust their goods to specific consumer needs. This increases client satisfaction and gives businesses a competitive advantage in the market. Customization enables firms to produce unique and tailored products that appeal to individual interests, increasing consumer loyalty.

Product engineering also allows organizations to innovate and stay ahead of their competitors. The method requires constant improvement and adaptation to changing market circumstances. Businesses can enhance their products by studying client feedback regularly. This iterative strategy stimulates innovation and allows companies to launch new features and technologies that set them apart from competitors.

Product engineering also contributes to better resource utilization. Businesses can eliminate waste, save money, and increase efficiency by optimizing the product development process. Product engineers may identify and eliminate bottlenecks with careful planning and testing, resulting in increased productivity and a shorter time-to-market.

Furthermore, product engineering emphasizes dependability and quality. Engineers can detect and correct potential defects or weaknesses in the product by conducting thorough testing and prototyping. This ensures clients obtain a reliable, long-lasting product that suits their needs. An emphasis on quality also helps firms establish a solid reputation, which leads to improved client trust and repeat purchases.

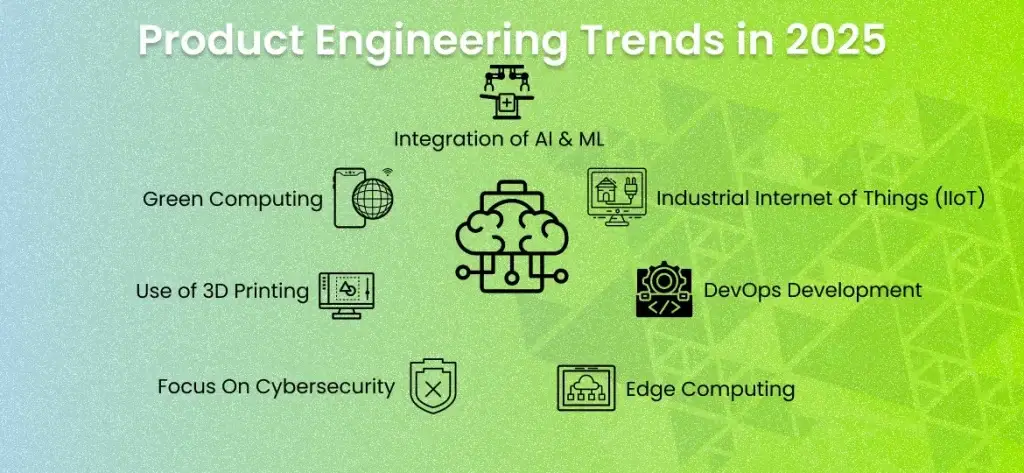

Significant Trends of Digital Transformation in Product Engineering

Integration of AI & ML

Machine learning, a type of AI, plays a vital role in product development. Machine learning algorithms can scan enormous datasets to detect patterns, learn from them, and make predictions or judgments without explicit programming. Machine learning can automate design optimization, anticipate product performance, and improve quality control in engineering. Companies can use machine learning to improve product design, cut costs, and provide superior items to the market.

Artificial intelligence (AI) is another transformational technology that will influence the future of product engineering. AI in product design can evaluate massive volumes of data, discover trends, and make informed conclusions. In product design, AI algorithms improve designs, offer novel ideas, and simulate product performance before prototypes.

Industrial Internet of Things (IIoT)

The rapid progress of technology has resulted in the introduction of several innovative technologies that are transforming product engineering. One such technology is the Internet of Things (IoT). IoT connects everyday objects to the internet, producing innovative products that collect data, communicate, and conduct automatic tasks. This connectivity has expanded product functionality, customization, and real-time monitoring possibilities.

The IIoT connects industrial equipment and processes, allowing for real-time data collection and analysis. This data enhances production operations, increases productivity, and reduces downtime. IoT technologies also enable the development of predictive maintenance systems, which can detect possible equipment faults before they occur.

Cloud-Native Development

The rise of cloud computing has changed the way product engineering is done. Cloud-based platforms offer scalable and adaptable architecture, allowing engineers to access computing resources remotely. This allows for collaborative design and simulation, streamlined data management, and cost-effective scalability. Cloud computing enables firms to centralize engineering data, improve operations, and ease global cooperation.

Cloud-native development is a method of creating and delivering apps that are specifically intended to run on the cloud. This strategy takes advantage of cloud computing’s scalability, elasticity, and flexibility to build more agile and resilient applications. Cloud-native development is also vital to accommodate the expanding number of IoT devices and applications.

Use of 3D Printing

3D printing is gaining popularity in product engineering due to its capacity to manufacture complicated and personalized goods. 3D printing is used to prototype new goods, develop custom parts, and manufacture finished things. Custom-fit shoes and prostheses are two examples of customized products made with 3D printing.

Focus On Cybersecurity

As products become more connected, cybersecurity becomes a key problem. Product engineers are putting security elements into their designs to protect against cyberattacks. This includes setting up secure authentication processes, encrypting data, and updating software regularly.

Green Computing

Green computing is a practice that aims to lessen the environmental impact of computers. Product engineers are creating goods that are more energy efficient and use less material. This involves employing recyclable materials and developing things that can be disassembled to reduce e-waste.

DevOps Development

DevOps is a set of practices that combine software development and IT operations. DevOps seeks to shorten the system development life cycle while maintaining excellent software quality. DevOps is used to increase the speed and quality of product development.

Edge Computing

Edge computing is a distributed computing concept that moves computation and data storage closer to its source. This minimizes latency and bandwidth needs, making it suitable for real-time data processing and autonomous systems. Edge computing is growing more significant as the number of IoT devices and apps increases.

Agile Product Development

Agile approaches have become essential to product development, allowing organizations to respond swiftly to changing market conditions. Agile product development entails iterative and incremental approaches emphasizing cooperation, adaptability, and consumer feedback. Organizations that embrace an agile approach can cut time-to-market, improve product quality, and increase customer happiness.

Industry 4.0 Solutions

Industry 4.0 refers to the manufacturing industry’s digital transformation, which combines automation, data interchange, and IoT. Organizations that use Industry 4.0 solutions in product engineering can achieve seamless integration of design, production, and supply chain processes. This improves efficiency, reduces time-to-market, and expands customization options.

Digital Twins Technology

Digital twin technology allows for the production of virtual replicas of physical objects, processes, or systems. Engineers may mimic and study product behaviour over its lifecycle by integrating the real and digital worlds. This enables predictive maintenance, real-time monitoring, and continual improvement. Digital twins improve product design, optimize performance, and allow quick prototyping, ultimately leading to higher-quality products.

Data-Driven Product Development

Data-driven product development uses massive amounts of data gathered throughout the product’s lifespan to inform decision-making. Organizations can get significant insights into consumer demands, product performance, and market demand by collecting and analyzing data from various sources, including customer feedback, sensor data, and industry trends. These data enable businesses to make informed decisions, prioritize product enhancements, and provide individualized consumer experiences.

Virtual Prototyping

Virtual prototyping has transformed the product development process by allowing engineers to generate digital versions of their products for visualization, validation, and testing. Virtual prototyping will enable organizations to save time and resources by eliminating the need for physical prototypes. Engineers can identify and correct design faults early in the development cycle by simulating product behaviour, which results in a shorter time-to-market, lower costs, and higher product quality.

Conclusion

To summarize, the future of product engineering is packed with exciting opportunities and breakthroughs. With the rapid advancement of technology, we should expect to see more innovative and efficient items invented and created. Artificial intelligence and machine learning will transform how goods are designed, allowing for greater customization, personalization, and functionality.

Furthermore, 3D printing and virtual reality will improve the prototyping and testing processes, resulting in shorter production cycles and lower costs. Moreover, the emphasis on sustainability and environmental awareness will create eco-friendly products and processes, assuring a greener future. Overall, product engineering has the potential to alter multiple industries and contribute to a more technologically advanced and sustainable planet.

Ready to develop your product and implement the latest trends for digital transformation? Reach out to Echoinnovate IT.

FAQs: The Future of Product Engineering: Embracing Digital Transformation

How is digital transformation impacting product engineering?

Digital transformation is revolutionizing product engineering by integrating AI, IoT, and cloud computing, enabling faster development, automation, and improved efficiency.

What are the key benefits of adopting digital transformation in product engineering?

Key benefits include reduced time-to-market, cost savings, enhanced product quality, and increased agility to adapt to market changes.

What challenges do companies face when implementing digital transformation in product engineering?

Common challenges include high initial investment, skill gaps, integration complexities, and resistance to change.